Reciprocating Air Compressor

A reciprocating air compressor uses piston-driven crankshafts to pressurize air and other gases, increasing their density while decreasing their volume. Air compression makes materials like natural gas easier to store, transport and use effectively.Reciprocating compressors store the pistons inside cylinders. Each cylinder has a closed end next to the cylinder head and is finished at the other end with a movable piston.

Working

The valves of the cylinders are located at the bottom of the compressor’s valve pockets. During the first stage of compression, air moves into the cylinder via a suction valve, triggered by the movement of the piston. When the piston moves downward, it creates a vacuum between the piston top and cylinder head. This causes the inlet valve to open and low-pressure gas fills in. During this time, inlet valves remain open and discharge valves remain closed.

Next, the piston moves upward forcing the inlet valve to close and the gas is trapped in the cylinder. As the piston moves further the area between the piston head and cylinder reduces which results in gas compression. When the gas pressure exceeds the discharge valve spring resistance, it opens and the gas is transferred to the receiver. The same process is repeated.

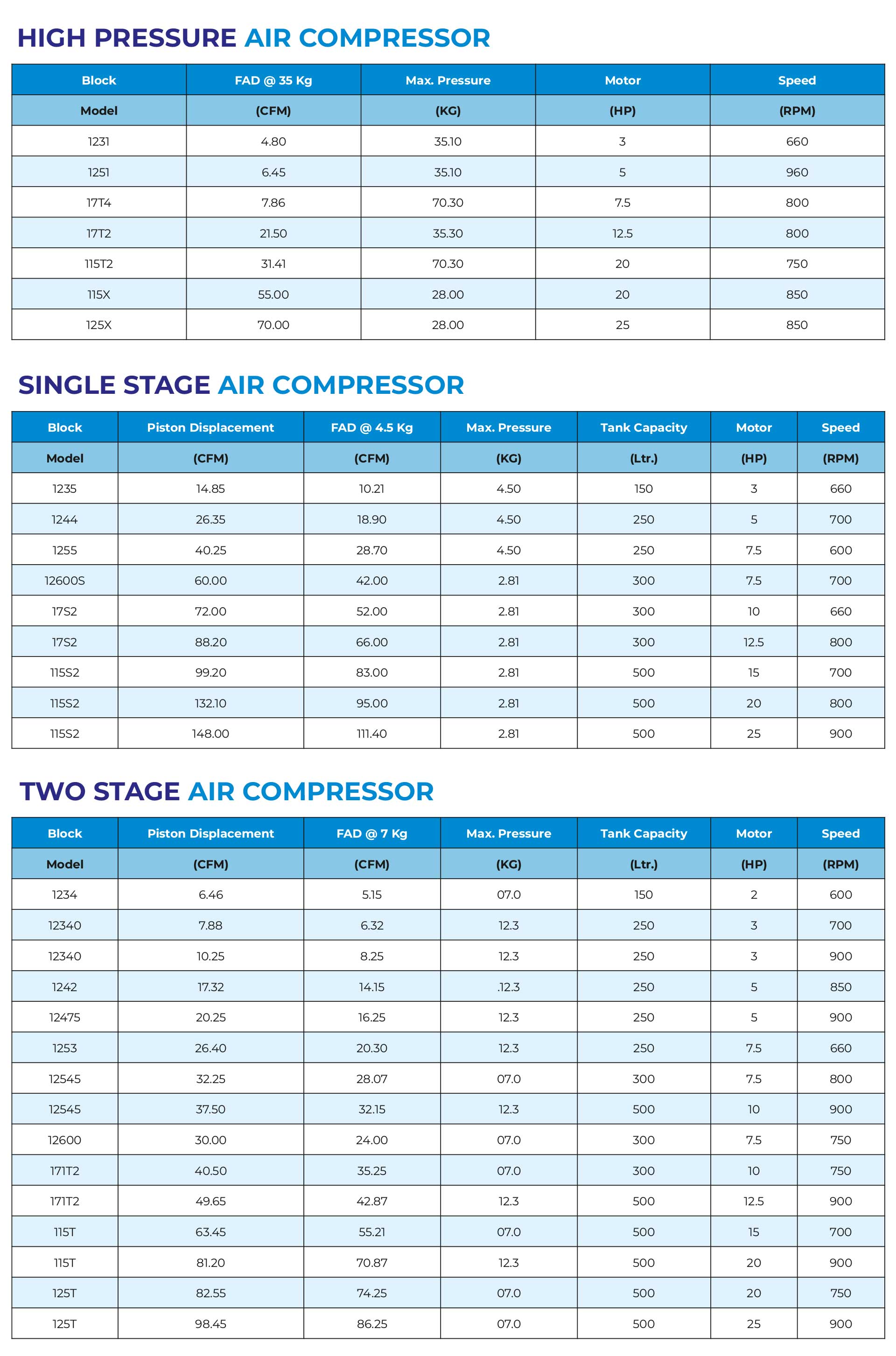

Specification

One of the important reciprocating compressor basics to be aware of is the duty cycle. The duty cycle is determined by taking the time the compressor spends loaded and comparing it to the time the machine runs while completely unloaded or turned off. Reciprocating compressors are only designed for a 60% to 70% full-load time and should be unloaded the rest of the time.

Data Sheet